4 Causes of Failure

Over the past 25 years, we have noticed a pattern as we repair fire hydrants. They

very predictably fail in the same four areas.

If we concentrate our efforts to remedy the problems in these same four areas, we

can then offer you a Long Life Fire Hydrant.

Incredibly, the four areas of failure can all be attributed to:

ONE COMMON CAUSE: ELECTROLYSIS

ELECTROLYSIS DEFINED*

The movement of d-c electricity through a substance or its container. Electrolysis

can be useful for producing results such as storage battery operation or electroplating.

However, it can also cause severe damage. Whenever there are two electrical conductors

and moisture, d-c electricity flow continues (electrons from - to +), one of the

conductors will have material removed (pits and holes). The eaten away areas are

called corrosion areas. To avoid electrolytic corrosion, one must remove the attraction

and seal off (insulate) the conductors or use conductors with the same activity

level.

*Source: Modern Refrigeration, Air Conditioning, pg. 964

(In other words, when you put brass in contact with either cast iron or steel in

a fire hydrant, and add moisture, they set up electrolysis and "rust" together.)

THE FOUR AREAS OF ELECTROLYSIS AND FIRE HYDRANT FAILURE:

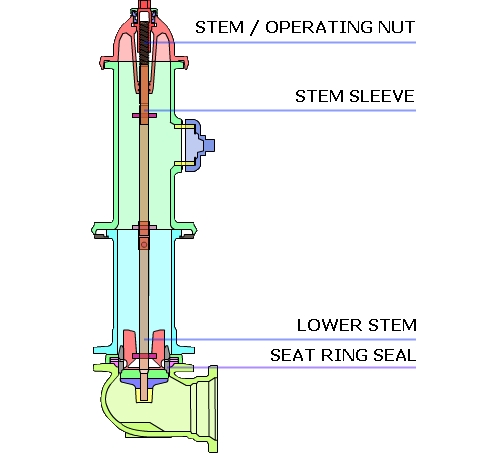

- STEM/OPERATING NUT - The stem "rusts" to the operating nut, and is the cause of

"hard to operate" in many cases. Results of this condition are rounded off pentagon

or square wrench nut, twisted off operating nuts, and twisted stem stress to the

point of failure of the stem anti-rotation device. The hydrant can become locked

and completely inoperative. Moisture is typically admitted by the stem sleeve cracking.

- STEM SLEEVE - The stem sleeve is a thin brass tube slid over the steel upper stem,

to provide a smooth seal for the bonnet/stem juncture. Electrolysis occurs between

the brass stem sleeve and the underlying steel stem. The lower 1/2" of the stem

sleeve is not sealed against moisture. Water collects underneath the sleeve, rust

forms and grows, and the stem sleeve cracks. Now water is able to flow through the

sleeve and into the operating nut area and wash out the lubricant, resulting in

the problems in 1. above. The stem sleeve can become so loose that it migrates upward

and locks up the operating nut. A dry, unlubricated sleeve can also make the hydrant

very difficult to operate.

- LOWER STEM - One of the worst areas for stem rust, due to the bottom few inches

contain the anti-rotation device, the drain valve, and hydrant valve. Electrolysis

occurs between the brass drain valve and the steel stem. Rust here typically disables

the anti-rotation device, or allows the stem to bend when opening pressure is applied

from above. Stems that are designed to slide thru the drain lever can become locked

to the point that they bend or break the drain lever. Rust here is further aggravated

by opening the hydrant, the resulting stream of water flowing thru the elbow flushes

away old stem rust, and new rust is now initiated. Coastal areas are particularly

vulnerable to lower stem rust, since the lower barrel of the hydrant is typically

filled with standing water from a high water table. Water allowed in through the

drain holes becomes mixed with mud, bacteria, acids, etc. and is highly corrosive

to the stem. It can also contaminate drinking water.

- SEAT RING SEAL COMPRESSION AREA - A nightmare area for the fire hydrant repairman.

Sadly, this is a very common occurence. Electrolysis occurs in the contact area

of the brass seat ring and the cast iron hydrant elbow. A pitted surface here will

not allow proper sealing of the seat o-rings or gasket, and the hydrant will leak.

New seat o-rings, new seat ring, new main valve, etc. will not fix the problem.

Leaks here may be undetected because water flows out the drain holes and is not

visible from the groundline. Repairs are further complicated by the "locking" of

the seat ring by the rust from the mating hydrant elbow., making the seat ring very

difficult to remove for repairs. Most seat wrenches provided by the manufacturer

are not effective in removing these locked in seat rings. Over torque of the seat

wrench can result in injuries and even further damage internal parts.

Millions of gallons of water are lost annually due to Number 4 above.